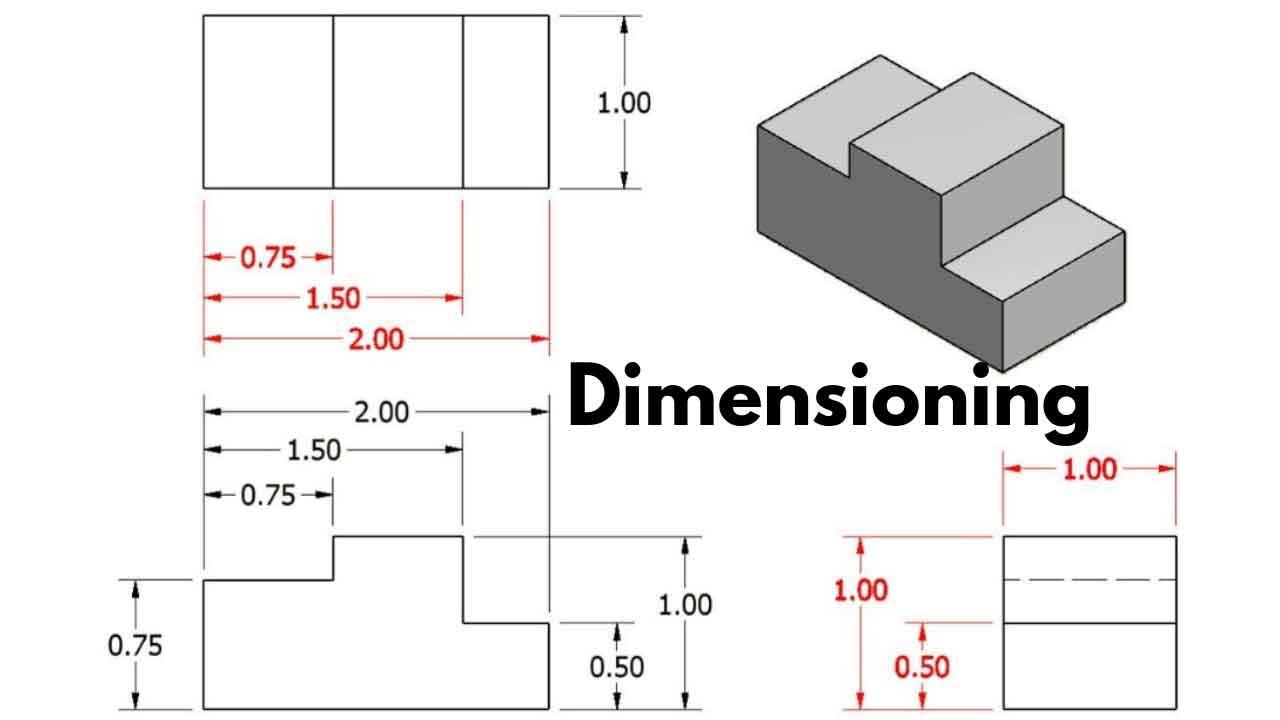

Have you ever looked at an engineering drawing and felt like you were staring at a foreign language? While the lines and symbols might seem cryptic at first glance, they hold the key to building the world around us. One of the most fundamental aspects of these drawings, and the language of engineering itself, is the art of dimensioning. It’s not just about numbers on a page; it’s about precisely communicating the size, shape, and location of every component in a design.

Image: www.youtube.com

This article delves into the world of dimensioning in engineering drawings, exploring the rules, conventions, and best practices that ensure successful and accurate communication. From the basics of dimensioning techniques to advanced concepts like geometric tolerances, this guide provides a comprehensive understanding of this crucial aspect of engineering design.

The Foundation of Dimensioning: Basic Concepts and Rules

Like any language, dimensioning has its own set of grammar and rules. These rules ensure clarity and consistency, preventing confusion and misinterpretations that could lead to costly errors in manufacturing.

1. The Dimension Line: The Foundation of Precision

The dimension line is the cornerstone of dimensioning, acting as the bridge between the drawing and the actual object. It’s a thin, solid line with arrowheads at each end, extending from one point to another on the drawing. The dimension line represents the distance between two points, with the dimension value written in between the arrowheads.

2. Extension Lines: Connecting to the Drawing

Extension lines, as their name suggests, extend from the object to the dimension line. They are thin, solid lines that indicate the points between which the measurement is taken. Extension lines must be perpendicular to the dimension line and extend slightly beyond it, creating a visual connection to the measured point.

Image: keneducation.in

3. Dimension Values: The Language of Measurement

The dimension value is the numerical representation of the distance between two points, typically expressed in millimeters (mm). It’s placed above or below the dimension line, centered and parallel to it. The dimension value must be legible and clearly visible within a clear space free from overlapping lines.

4. Dimensioning Units: Ensuring Consistency

Dimensioning units establish the standard of measurement for a drawing. In most engineering contexts, the standard unit is millimeters (mm). However, alternative units like inches (in) may be used in specific applications or industries. Regardless of the unit chosen, it’s crucial to maintain consistency within a single drawing.

5. Dimensioning Types: Defining Spatial Relationships

Dimensioning is not just about measuring lengths; it also conveys the spatial relationships between different components. Common dimensioning types include:

- Linear: Measuring a straight distance between two points.

- Angular: Measuring the angle between two lines or surfaces.

- Radial: Measuring the distance from a center point to a point on a circle.

- Diametral: Measuring the diameter of a circle or cylindrical feature.

- Chain: Placing multiple dimension lines in a chain to define a series of distances.

- Baseline: Establishing a common baseline from which all other measurements are taken.

- Ordinate: Measuring distances from two perpendicular lines, often used for locating holes.

Beyond the Basics: Advanced Dimensioning Techniques

While the fundamental rules of dimensioning provide a solid foundation, mastering the language of engineering requires delving into more advanced techniques.

1. Geometric Tolerances: Defining Acceptable Variation

No manufacturing process can achieve absolute perfection, so tolerances are essential for specifying acceptable variations in size, form, and location. Geometric tolerances, often expressed through symbols and numerical values, define these acceptable limits. Commonly used geometric tolerance symbols include:

- Circular runout (CIR): Controls the variation of a cylindrical surface as it rotates around its axis.

- Positional: Controls the location of a feature relative to a datum.

- Parallelism: Controls the parallelism between two surfaces.

- Perpendicularity: Controls the perpendicularity between two surfaces.

2. Datum Systems: Establishing a Reference Frame

Datum systems provide a stable reference frame for positioning and tolerancing features on a drawing. A datum is a theoretically perfect plane, line, or point that serves as a reference for all other measurements. Datum features on the drawing, such as a flat surface or a cylindrical hole, represent these theoretical datum references.

3. Dimensioning Practices

- Dimensioning Hidden Features: When a feature is not visible in the current view of the drawing, it’s often necessary to dimension it using hidden lines. These are thin, dashed lines that represent the hidden feature and are typically used for dimensioning internal features or features on the opposite side of the object.

- Dimensioning with Leaders: Leaders are line segments used to connect dimension values to specific points on the drawing. They are typically drawn at a 45-degree angle and end with an arrowhead pointing to the measured point.

- Dimensioning Chamfers and Fillets: Chamfers and fillets are frequently used to improve the aesthetics or structural integrity of components. They are dimensioned using a dedicated format, specifying the angle and length of the chamfer or the radius of the fillet.

The Power of Precision: The Impact of Dimensioning on Engineering

Dimensioning is not merely a cosmetic element of engineering drawings; it plays a vital role in ensuring the success of a design. Precise dimensioning ensures that manufactured components fit together properly, preventing costly rework or assembly issues.

- Manufacturing: Dimensioning guides the manufacturing process, providing clear instructions for machine operators to create components according to the specified dimensions.

- Assembly: Accurate dimensioning ensures that parts align correctly during assembly, minimizing the need for adjustments or modifications.

- Functionality: Dimensioning defines the overall size and shape of components, influencing their functionality and performance.

- Quality Control: Dimensioning provides a basis for inspection and quality control, ensuring that manufactured components meet the specified standards.

Trends and Developments in Dimensioning

The field of engineering is continually evolving, and dimensioning practices are no exception. As technology advances, new tools and methods are emerging to enhance the efficiency and accuracy of dimensioning.

- CAD software: Computer-aided design (CAD) software has revolutionized the process of creating and dimensioning drawings. CAD tools offer automated dimensioning capabilities, simplifying the process and enhancing precision.

- 3D Modeling: 3D modeling provides a more immersive and interactive way to visualize and dimension objects. 3D models can be used to simulate assembly procedures and identify potential interference issues before manufacturing.

- Digital Manufacturing: Advances in digital manufacturing, such as 3D printing, are changing the way products are manufactured. Dimensioning plays a crucial role in ensuring that digital models are translated accurately into physical objects.

Rules For Dimensioning In Engineering Drawing

Conclusion

Mastering the language of dimensioning is essential for anyone involved in engineering design, whether you are a seasoned professional or a budding engineer. A firm understanding of dimensioning rules and conventions ensures that your designs are communicated effectively, leading to successful manufacturing, assembly, and product performance. By embracing the principles outlined in this article, you can unlock the secrets of engineering drawings and harness the power of precision to create innovative and functional designs.

Now, go forth and explore the world of dimensioning, continuing to refine your understanding of this vital aspect of engineering communication. The journey of mastering dimensioning is an ongoing one, filled with new challenges and opportunities to express your creativity and technical proficiency.