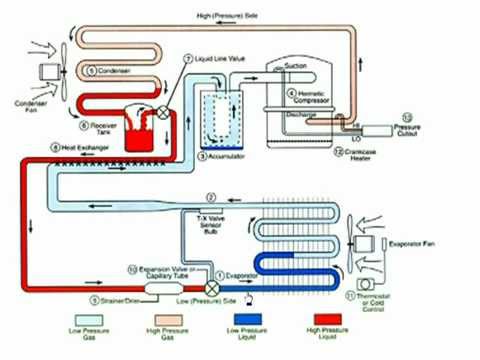

As an HVAC technician, I’ve spent countless hours troubleshooting systems, and one of the most crucial aspects of that process is understanding subcooling and superheat. These seemingly complex terms represent vital parameters in a refrigeration system that can significantly impact performance and efficiency. Imagine a perfectly functioning refrigeration system where every part works in harmony, but then imagine a scenario where the system isn’t quite right, and the compressor is struggling to handle the workload, and the evaporator is only partially working, all because of subcooling and superheat. This is where your understanding of these parameters comes into play to optimize your system’s performance.

Image: www.youtube.com

In this comprehensive guide, we’ll dive deep into the world of subcooling and superheat, explaining what they are, why they matter, and how to achieve optimal levels for your refrigeration systems. We’ll guide you through the process of understanding, calculating, and adjusting these parameters, ensuring you possess the knowledge to effectively troubleshoot and optimize any HVAC system.

Understanding Subcooling and Superheat

What is Subcooling?

Subcooling, in simple terms, is the process of cooling the liquid refrigerant below its saturation temperature. Think of it this way: when a substance transitions from a liquid to a gas, it does so at a specific temperature called the saturation temperature. Subcooling means taking the liquid refrigerant below that point, resulting in a cooler, denser liquid. This denser liquid refrigerant then travels to the expansion valve, where it is ready to absorb heat from the space you want to cool.

What is Superheat?

Superheat, on the other hand, refers to the temperature difference between the refrigerant vapor leaving the evaporator and the saturation temperature at the pressure at which the vapor is leaving the evaporator. Essentially, you are heating the refrigerant vapor above its saturation temperature, which ensures that it exists fully in a vapor state as it goes to the compressor. This is important for preventing liquid refrigerant from entering the compressor, as this could damage the system.

To visualize this, imagine a pot of water on the stove. As you heat the water, it reaches its boiling point, the saturation temperature, and turns into steam. Now, if you continue heating the steam, you are essentially superheating it. This extra heat makes sure the water vapor stays in a vapor state, and isn’t able to turn back into liquid form. This is the same concept in refrigeration systems – we need to superheat the refrigerant vapor to ensure it’s in the right state for optimal efficiency.

Image: www.acservicetech.com

Why are Subcooling and Superheat Important for HVAC Systems?

Subcooling and superheat are not merely abstract concepts. These parameters play a critical role in:

- Refrigeration System Efficiency: Subcooling and superheat directly affect the amount of heat the system can absorb and remove, maximizing the system’s efficiency. For example, a higher subcooling level can increase the refrigerant flow rate, leading to more heat removal.

- Compressor Performance: Subcooling and superheat directly impact the load on the compressor, hence, a proper balance ensures the compressor operates efficiently while preventing damage.

- System Reliability: Incorrect subcooling or superheat can lead to inconsistent performance, system failures, and refrigerant leaks.

- Capacity: Optimizing subcooling and superheat enables the system to deliver optimal cooling capacity, ensuring that your space is adequately cooled.

How to Get Optimal Subcooling and Superheat in Your HVAC System

Now that we understand the significance of subcooling and superheat, let’s explore how to achieve the optimal levels for your HVAC system. Remember, the ideal values for subcooling and superheat can vary depending on the system’s design, refrigerant type, and operating conditions. We will primarily focus on how to measure and adjust these parameters practically.

Measuring Subcooling

To measure subcooling, you’ll need a set of gauges and a thermometer. Here’s a step-by-step guide:

- Connect Gauges: Connect your gauges to the refrigeration system’s high-pressure side. Ensure they are properly calibrated and ready for use.

- Locate Liquid Line: Identify the liquid line coming from the condenser. The liquid line is usually smaller than the suction line.

- Measure Temperature: Using the thermometer, carefully measure the temperature of the liquid line. You need to ensure that the thermometer is resting on the line for an accurate measurement.

- Read Gauges: Simultaneously, take a reading from the high-pressure gauge. This will provide the pressure at which the refrigerant is flowing in the liquid line.

- Calculate Subcooling: To calculate subcooling, subtract the temperature reading from the thermometer from the saturation temperature corresponding to the pressure reading from the high-pressure gauge. You can use a refrigerant chart to find the saturation temperature for the given pressure. For example, if the thermometer reads 40°F and the saturation temperature at the measured pressure is 45°F, then the subcooling is 45°F – 40°F = 5°F.

Note that the refrigerant chart should match the refrigerant in use in your system.

Measuring Superheat

Similarly, you can measure superheat using gauges and a thermometer. Follow these steps:

- Connect Gauges: Connect your gauges to the refrigeration system’s low-pressure side.

- Locate Suction Line: Locate the suction line coming from the evaporator. This line is often larger than the liquid line.

- Measure Temperature: Measure the temperature of the suction line using the thermometer.

- Read Gauges: Take a reading from the low-pressure gauge. This represents the pressure of the refrigerant as it exits the evaporator.

- Calculate Superheat: To determine superheat, subtract the suction line temperature (measured with the thermometer) from the saturation temperature corresponding to the low-pressure gauge reading. This is analogous to the subcooling calculation; however, you are using the low-pressure gauge and the suction line temperature. For example, if the suction line temperature reads 50°F and the saturation temperature at the measured pressure is 45°F, then the superheat is 50°F – 45°F = 5°F.

Again, the refrigerant chart should match the type of refrigerant used in your system.

Adjusting Subcooling and Superheat

Once you’ve measured subcooling and superheat, you can adjust them as needed. There are a few common ways to make these adjustments:

- Expansion Valve Adjustment: The expansion valve plays a crucial role in regulating the flow of refrigerant. In most cases, you can adjust it using a small screw or bolt. Rotating or adjusting the expansion valve can have a significant impact on both subcooling and superheat. Be cautioned that incorrect adjustments could damage the valve.

- Condenser Fan Speed: The condenser’s job is to dissipate heat from the refrigerant. If the condenser is not working efficiently, it can result in low subcooling. You may be able to increase the condenser fan speed to improve the heat removal from the refrigerant.

- Refrigerant Charge: If the system is undercharged or overcharged, it will affect the refrigerant’s saturation temperature, impacting both subcooling and superheat. Consult manufacturer specifications or seek professional assistance for proper refrigerant charging.

- Compressor Speed: In variable speed compressors, adjusting the compressor speed can influence the refrigerant flow and pressure, impacting subcooling and superheat. However, this is often a more complex adjustment requiring specialized knowledge of the compressor system.

Remember, before making any adjustments, consult the system’s documentation and diagrams to understand the components and how they interact to achieve the optimal system operation. Consult a professional if you are unsure about these adjustments, as improper manipulation can compromise the system’s safety and efficiency.

Tips and Expert Advice

Here are a few tips and expert advice based on my experience as an HVAC technician:

- Practice Consistency: Always use the same method, tools, and references for measuring subcooling and superheat to maintain consistency in your readings.

- Monitor Change: After making adjustments, monitor the subcooling and superheat values regularly to ensure they are within the desired range.

- Consult Manuals: Refer to the system’s manufacturer specifications and manuals for recommended subcooling and superheat values, along with any adjustment procedures.

- Focus on System Behavior: Pay close attention to the system’s performance and behavior. If something seems off or doesn’t feel right, check the subcooling and superheat values, as they can offer valuable insights into potential problems.

By following these tips, you can improve your troubleshooting abilities and optimize the performance of your refrigeration systems. Understanding the nuances of subcooling and superheat will make you a more efficient and knowledgeable HVAC technician.

FAQs about Subcooling and Superheat

- What is the ideal subcooling and superheat? The ideal values for subcooling and superheat can vary depending on the system’s design, refrigerant type, and operating conditions. However, a typical range for subcooling is 5-10°F, while superheat is often between 10-15°F. Refer to your system’s manufacturer specifications for optimal values.

- What happens if subcooling is too high? If subcooling is too high, it can result in excessive liquid refrigerant being pulled into the compressor, leading to damage.

- What happens if superheat is too low? If superheat is too low, it can result in liquid refrigerant entering the compressor, which could cause damage.

- What happens if superheat is too high? If superheat is too high, it can reduce the system’s efficiency as it requires the compressor to work harder to bring the vapor down to the desired temperature.

- Can I adjust subcooling and superheat without professional help? It’s possible to adjust subcooling and superheat yourself if you have experience and understand the system’s operation. However, it’s always advisable to consult a qualified HVAC technician if you are unsure about any adjustments.

How To Get Subcooling And Superheat

Conclusion

Mastering the concepts of subcooling and superheat is crucial for any HVAC technician who wants to optimize system performance and efficiency. By understanding how to measure, adjust, and interpret these parameters, you can improve your troubleshooting skills and deliver exceptional results to your customers. Remember, consistently monitoring subcooling and superheat levels can help identify potential problems and prevent costly repairs.

Are you interested in learning more about subcooling and superheat and their impact on your HVAC system? Let us know in the comments below! We welcome your questions and insights!