Have you ever walked into a construction site and wondered about the massive steel beams that form the backbone of the building? Those sturdy pillars, known as I beams, are more than just metal bars; they are engineering marvels, carefully designed to withstand incredible forces and ensure the stability of structures. But with so many different sizes and weights, navigating the world of I beams can be daunting. Fear not! This comprehensive guide will equip you with the knowledge to understand the nuances of I beam sizing and weight, empowering you to make informed decisions for your next project.

Image: mavink.com

Imagine building a skyscraper. Without the precise calculations of I beam sizes and weights, the entire structure could collapse. Every beam plays a vital role, contributing to the strength and stability of the building. Understanding the characteristics of these essential components is crucial for architects, engineers, and anyone involved in construction. This guide is your roadmap through the intricate world of standard I beam sizes and weights, providing you with the information you need to build with confidence.

Delving Deep into the World of I Beam Dimensions

I beams are named for their cross-sectional shape, which resembles the capital letter “I”. The unique design is intentionally crafted to maximize strength and efficiency, distributing weight evenly and providing superior resistance to bending and stress. The key components of an I beam include:

- Flange: The horizontal top and bottom sections of the beam.

- Web: The vertical section connecting the flanges.

The standard I beam sizes and weights are classified according to a standardized system called the “American Standard Beam” (ASB). The ASB system categorizes I beams based on their weight per unit length, typically expressed in pounds per foot (lbs/ft). Common ASB designations include:

- W-shape I beams: These are the most frequently used I beams in construction, featuring a wide range of sizes and weights. “W” stands for “wide flange,” indicating the wider flange design compared to S-shape beams.

- S-shape I beams: These beams have narrower flanges, often used in situations where space is limited. “S” represents “standard,” referencing the more traditional design.

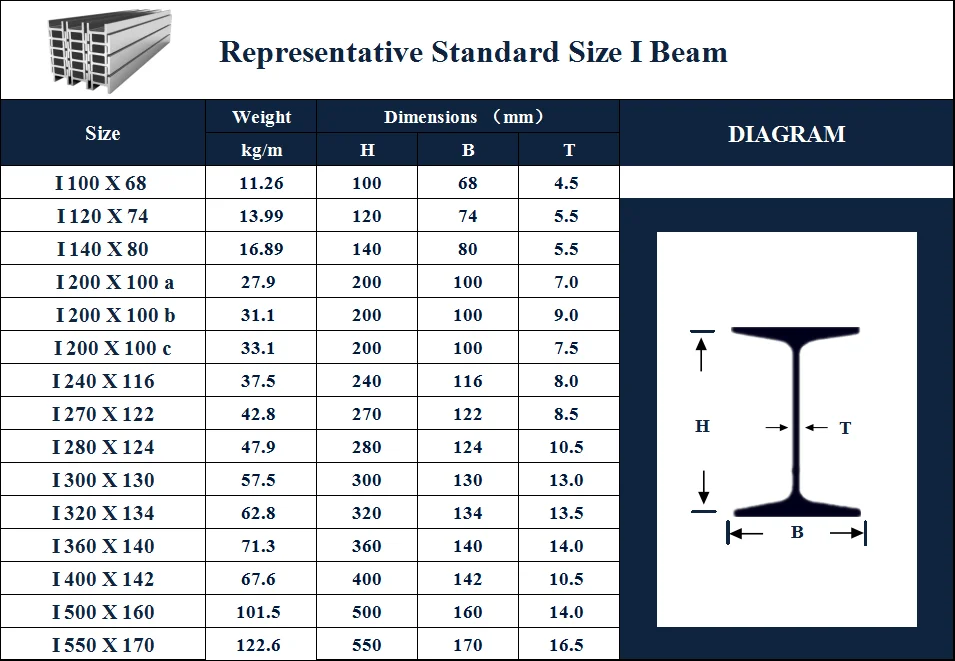

Decoding the Secrets of Standard I Beam Size and Weight Charts

Navigating a standard I beam size and weight chart can feel like deciphering an ancient text! But don’t worry, with a little help, it’s much easier than it seems. Here’s how to understand the charts:

- Nominal Depth: This refers to the overall height of the I beam, usually measured in inches. The depth is the most crucial factor in determining the beam’s load-bearing capacity.

- Weight per Foot: The chart will display the weight of the I beam per foot of length, typically in pounds (lbs/ft).

- Flange Width: This measurement indicates the width of the top and bottom flanges.

- Web Thickness: This value represents the thickness of the vertical web that connects the flanges.

- Moment of Inertia: This is a technical term representing the beam’s resistance to bending, a key factor in choosing the right beam for your project.

Navigating the Numbers: Understanding Beam Selection

The process of selecting the right I beam is a delicate dance between strength and economy. Here’s a practical breakdown of the factors to consider:

- Load Calculation: The first step is to calculate the weight and load that the beam will be supporting. This can include the weight of the structure itself, furniture, equipment, and the anticipated load from people or vehicles.

- Span Length: The distance between support points for the beam, known as the span length, directly impacts the load-bearing capacity of the beam. Longer spans require larger beams to distribute the weight effectively.

- Material Properties: I beams are typically made of steel, but the type of steel can vary depending on the project requirements. Carbon steel is a common choice due to its affordable strength, while higher-grade steels like A992 are ideal for high-load applications.

Image: wegadgets.net

I Beam Size and Weight Calculation: A Practical Example

Let’s say you’re constructing a deck spanning 12 feet, with an estimated load of 500 pounds per square foot. Here’s a simplified example of how to choose an appropriate I beam:

- Calculate the total load: 12 feet x 500 pounds/square foot = 6,000 pounds. This is the total weight the beam needs to support.

- Consider the span length: The beam spans 12 feet, so we need to select an I beam capable of handling this distance.

- Refer to an I beam size and weight chart: By consulting the chart, you’ll find an appropriate beam that can handle the calculated load and span, balancing strength and cost.

Remember, this is a simplified illustration, and accurate calculations should be performed by a qualified structural engineer for any real-world project.

I Beams Beyond Construction: Exploring Diverse Applications

While I beams are the backbone of countless buildings, their utility extends far beyond just construction sites. Here are some fascinating applications:

- Bridges: I beams are the foundation of many bridges, providing the strength required to safely span over rivers, valleys, and highways.

- Aerospace: I beams are used in airplane manufacturing, contributing to the frame and internal structural support.

- Automobiles: I beams are a key component in shaping the chassis and crumple zones of vehicles, enhancing crash protection.

Expert Insights for a Deeper Understanding

The world of I beams can seem complex, but with expert guidance, it becomes much clearer. Here are some insights from seasoned professionals:

- “Always consult with a structural engineer for accurate load calculations and beam selection,” advises a renowned structural engineer, emphasizing the importance of professional oversight.

- “The choice between W-shape and S-shape beams depends largely on the available space and the specific needs of the project,” explains a seasoned civil engineer.

Standard I Beam Size And Weight Chart

https://youtube.com/watch?v=2PcIfBe3ee0

Unlocking the Potential of I Beams

By understanding the nuances of standard I beam sizes and weights, you can approach construction with confidence. Take the time to explore the resources available, learn from the experts, and always prioritize safety and accuracy when working with these critical structural components. With this knowledge, you’re not just building a structure; you’re building a foundation for a safer, more durable, and sustainable future.